Clemson University Students Design Ergonomic O-Ring Assembly to Reduce Worker Repetitive Strain Injury

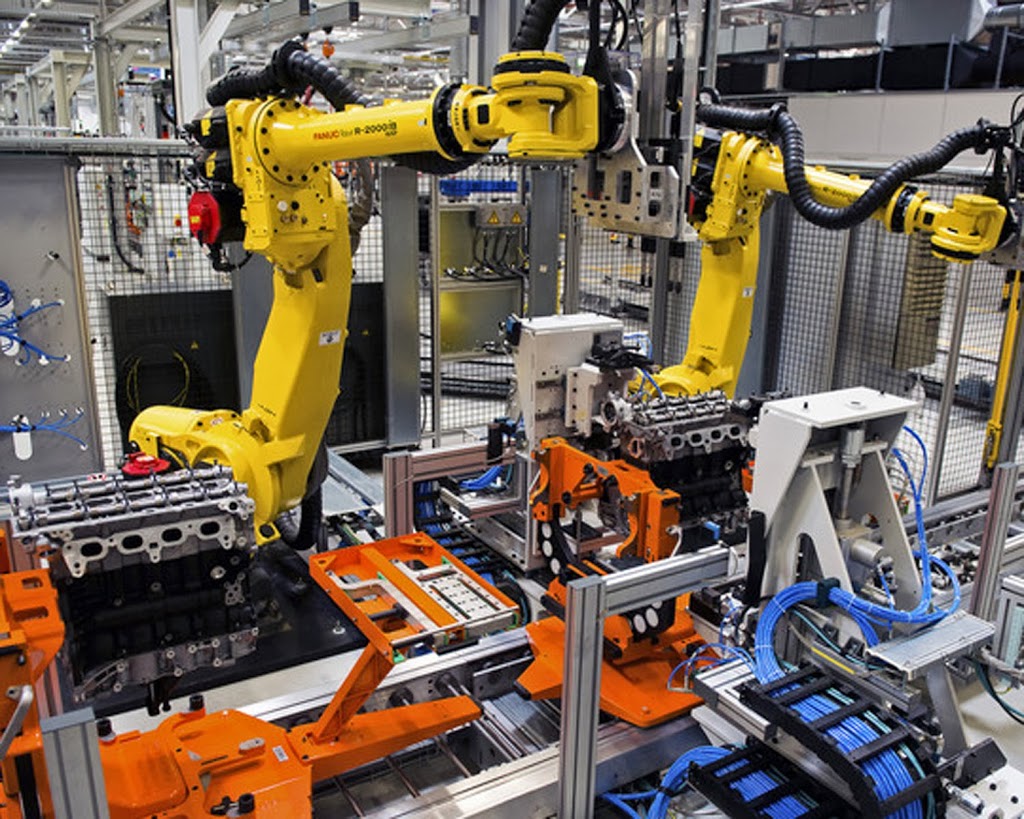

Clemson University students design ergonomic o-ring assembly to reduce worker RSI stemming from prolonged  repetitive, awkward and forceful movements. Clemson University’s capstone design project provides students with a realistic design experience that allows them to integrate and apply disciplinary material they have learned during their engineering program to synthesize a new product, device or process. The innovative Clemson design lends itself to be run in automatic, semi manual and fully manual modes along with hard automation or robotics. The advantage is to have a machine with short and long run capabilities that will automate the installation of O-ring seals and remove repetitive stress injuries (RSIs) during the o-ring assembly. O-ring seals are used in many products, including valves, and home appliances, and are integral to the manufacturing of devices in numerous industries. American Grippers Inc is proud to participate in sponsorship opportunities when they have the potential to lead to innovation and the advancement in manufacturing technologies. AGI has provided equipment to support a Capstone design project performed by students at Clemson University.

repetitive, awkward and forceful movements. Clemson University’s capstone design project provides students with a realistic design experience that allows them to integrate and apply disciplinary material they have learned during their engineering program to synthesize a new product, device or process. The innovative Clemson design lends itself to be run in automatic, semi manual and fully manual modes along with hard automation or robotics. The advantage is to have a machine with short and long run capabilities that will automate the installation of O-ring seals and remove repetitive stress injuries (RSIs) during the o-ring assembly. O-ring seals are used in many products, including valves, and home appliances, and are integral to the manufacturing of devices in numerous industries. American Grippers Inc is proud to participate in sponsorship opportunities when they have the potential to lead to innovation and the advancement in manufacturing technologies. AGI has provided equipment to support a Capstone design project performed by students at Clemson University.

Workers RSI cost businesses over $700 million yearly and have soared over 30 percent last year. To combat repetitive strain injuries that have afflicted workers, many companies have adopted ergonomics programs, which seek to adapt automation o-ring assembly processes. Specialists in ergonomics have long agreed that continued and repeated stress to joints and tendons result in a range of RSI ailments, including tendonitis, arthritis and carpel tunnel syndrome. Workers experiencing these injuries experience medical and financial setbacks, but they are not alone in their suffering.

Manufacturing firms are affected by soaring medical costs and production losses as a result of the RSIs their employees endure. “One great advantage of implementing O-ring assembly equipment” points out AGI President Peter Farkas, “is that workers place less stress on their hands.” He continues, “For years we have been aware of the advantages of using automated technologies; however, the full benefits of automation have not yet been realized as certain manual operations have proven difficult to eliminate until now. O-ring seal installation has been one of these.” For him and other innovators at AGI, it is exciting to be able to offer manufacturers new technologies at affordable prices.

The two different devices now offered to allow the positioning and sealing of O-rings of various sizes. The technology can be employed in semi-automatic single-station hand assists and fully-automated assembly line, and can be implemented in a wide range of manufacturing industries. AGI’s O-ring assembly tools come in two sizes: the AGP-6-OR (which has six jaws) and the AGP-8-OR (which has eight). These pneumatic grippers can accommodate placement applications from 3 to 12 inch I.D. Both are designed to facilitate part ejection and part seating and are perfect for installations where an ejector is needed after the part is positioned, or when a seal needs to be placed down a long shaft. Independent piston technology and double-acting spreading jaws allow the pneumatic devices to place very little stress on the O-Rings.

The O-Rings, as a result of the octagon–shape they take on, undergo significantly less deformation than they would if applied through alternative means of assembly. Additionally, because the strokes are adjustable to precise measurements, there is little risk of over-expansion.