Cure for manufacturing downtime: MRO interchangeable parts.

Manufacturers who don’t include downtime in their total cost of operation are deceiving themselves about performance. When a student gets a grade of zero for missing an exam without making it up, it completely messes up the test score average.

The same is true of extended periods of machine downtime that shut down the entire assembly line—the manufacturer’s bottom line takes a big hit, if the manufacturer isn’t paying attention.

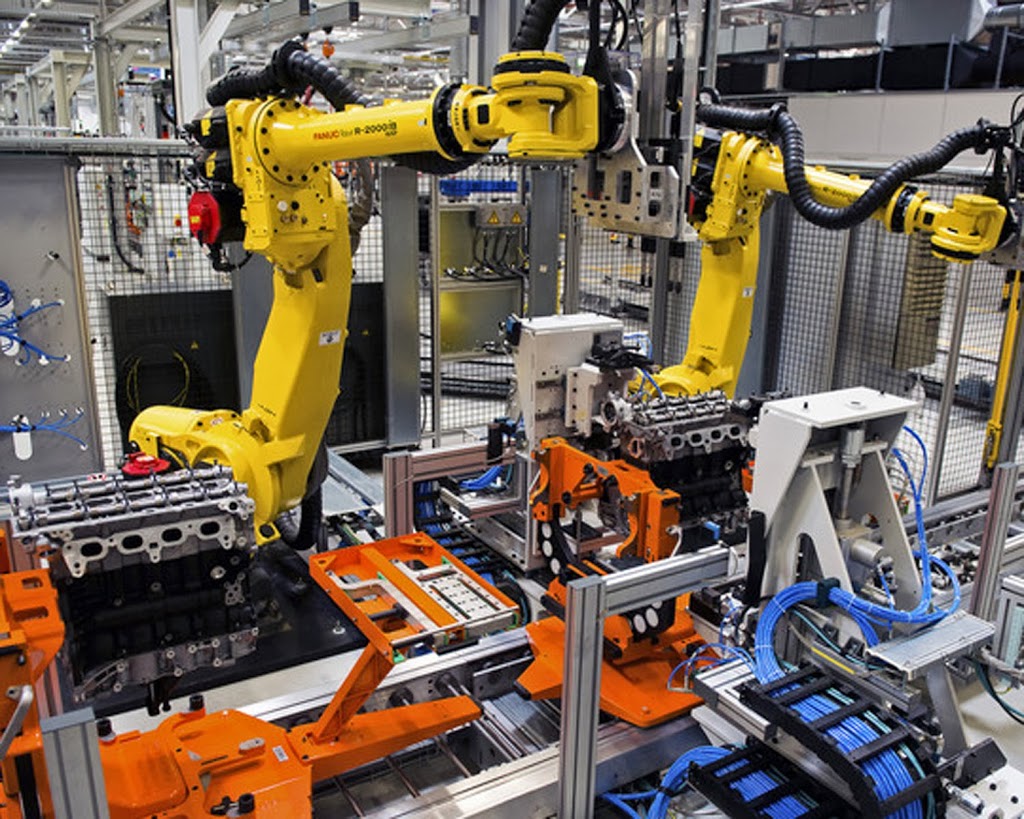

One of the most common causes of machine downtime occurs when machine components are not in stock and ordering replacements means a long lead time. Most suppliers of assembly and automation components do not stock parts and have long shipping lead times. It’s not an exaggeration to say that a long shipping lead time causing a shift or more worth of downtime is catastrophic. In this age of lean manufacturing and just-in-time inventorying, such a scenario is simply unacceptable but common place.

Because timely component replacement is increasingly critical, getting to know one’s component supplier is increasingly critical, too. In an article titled “Getting more from maintenance, repair and operations (MRO): knowing the capabilities of maintenance, repair and operations suppliers can help manufacturers keep costs down” in the March 2009 issue of Industry Week, Tom Armold, vice president of marketing and strategic accounts for Applied Industrial Technologies, contended that many manufacturers increasingly view their suppliers not only as firms that can offer a high level of product and service support but also partners that can help reduce operating costs.

According to the article, component suppliers are now expected to work closely with manufacturing companies to find solutions that will keep their plants operating profitably. Armold proposed several ways in which MRO component suppliers can help manufacturers reduce their costs.

One of these ways is offering solutions that positively impact the bottom line. Armold suggested that customers look for a partner that can expertise and technical know-how as well as a wide inventory of parts and equipment.

American Grippers Inc has made a conscious effort to make other pneumatic automation component suppliers’ discontinued parts available. AGI components are designed to be interchangeable for overall dimension, mounting and porting.

AGI stocks a wide variety of industrial automation products and components to keep our manufacturing partners’ operations in production. These include:

- Parallel and angular grippers

- Rotary actuators

- Mini-slides

- Linear actuator slides

- Pneumatic linear thruster slides

- Multi-motion actuators

- Pick and place components

- Tool changers

- Load limiters

- Feed escapements

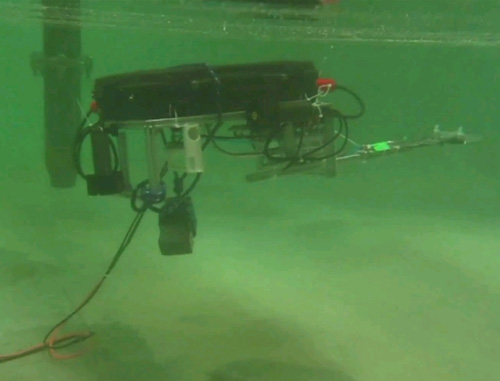

- Robotic end effectors

- Pneumatic linear actuators

- Pneumatic grippers

- Pneumatic parallel grippers

- Pneumatic rotary actuators

- Robotic tool changers

- Angular grippers

- Parallel grippers

- Robotic grippers