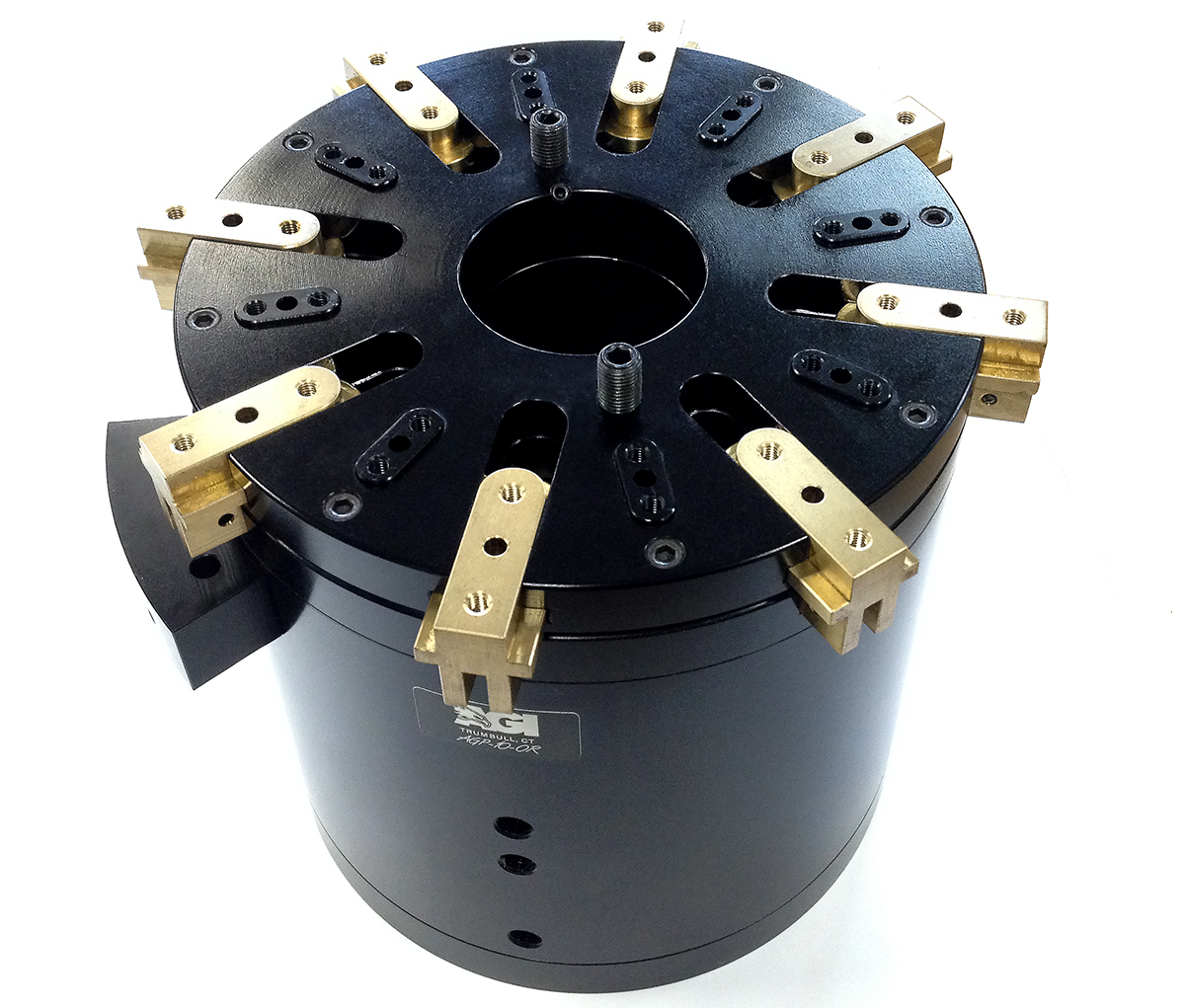

AGP-10-OR – Gripper for Placing O-Rings with through hole

Features & Benefits

- Jaws are T-Slot bearing supported to prevent jaw breakage and offer superior load bearing performance.

- Spreading jaws and Ejector jaws have independent pistons to provide exact timing of O-ring placement.

- Compact design with long adjustable stroke.

True parallel jaw motion for easy tooling and 2.25 inch Through hole.

PRODUCT SPECIFICATIONS

Design: Parallel, Double Acting, Synchronized Sealed Jaws, Through Hole

Stroke: Spread 1.625 in. adj. [42.9 mm]

Ejecting 0.55 in [13.9 mm]

Gripping Force Per Jaw @ 80 PSI [5.5 BAR]

Spreading jaws have 112-1230 lbs. force [each] @80 psi.*

Ejector jaws have 750 lbs. force [combined] @80 psi.

Time:

Close: 0.2 sec [0.2 sec]

Open: 0.2 sec [0.2 sec]

Pressure Range:

Low/High 30-100 PSI [2-7 BAR]

Temperature Range:

Low/High -20°/180°F [-28°/80°C]

Side Play: ± 0.001 [.03 mm]

Repeatability from center:

± .002 [.06 mm]

Loading Capacity: Static – Dynamic

Max Tensile T

160 lbs 45 lbs

[711 N] [200 N]

Max Compressive C

160 lbs 45 lbs

[711 N] [200 N]

Max Moment Mx

400 in/lb 100 in/lb

[45 Nm] [12 Nm]

Max Moment My

440 in/lb 120 in/lb

[50 Nm] [13 Nm]

Max Moment Mz

400 in/lb 100 in/lb

[45 Nm] [12 Nm]

Material: High Strength,Hard Coated

aluminum bronze alloys, Steel

Weight: 26 lbs [11.7 Kg]

* [ Depending where in the cycle of stroke it is measured. The farther the spread or opening of jaws, the stronger the force. This exponential force {curved} applies to all AGP-OR Grippers. Also, keep in mind these are ‘no’-friction numbers. Every application will entertain a different coefficient of kinetic friction depending on finger design, {height & length}, and should be taken into consideration during design stages of assembly equipment ].